One more expensive new part to break down.

The EPA establishes tighter emission standards, costs to consumers go up & viability of ICEs go down

By Perry Small, Raise a Hood

As I was walking into the door of the State of California Smog Test Center in Fresno, CA In 1985, I heard a voice say “hey you… got a minute?” I walked down the hall to a little office and sat down. The gentleman before me was the head Emissions Instructor and Proctor for the State of California Emissions for the Bureau of Automotive Repair. Hey says... “I have seen you here several times retacking your smog license test... You are having trouble passing?” It was my 3rd attempt and if I don’t pass this time, I will have to wait a year to be able to retake the test. He says to me... “Answer every question with this in mind... In a multiple-choice question... pick the answer that would lower the emissions the most out the tailpipe...” And Bam I did and passed. I went on latter teaching the 180 Hour Clean Air Course for California for over 10 years.

I mention this because I have seen hundreds of emission systems and have spent countless hours diagnosing and teaching Technicians why and how these systems work. We could get into the politics... but that is another story. Our current administration has again lowered the total emissions standard for ICE vehicles, that is bringing us closer to the European Union and other country standards. But let’s get to the meat of it. At Raise a Hood, we consider the politics… our focus is on the technology. why? because as an Automotive Service Professional you need to know… What the system is… How it works… and how do I know when it’s not functioning properly and finally… How do I diagnose and fix it! saving money!

Today we have ICE gasoline engine GPF. yes, I said it... and no I did not mean DPF... GPF, Gasoline Particulate Filter System. Coming to a Ford Product near you Soon! I have spent 2 days looking at Ford Training Syllabus regarding this system but for today we will show a Toyota version. I can not share the Ford system training video, I will have it soon for you all to see.

Let’s get after it!

Gasoline particulate filters (GPF) are based on the proven wall-flow technology of diesel particulate filters. While the purpose of DPF is to mitigate particulate emissions from diesel engines, GPFs were developed to reduce fine particulate emissions from gasoline vehicles.

GPFs have the same honeycomb structure as DPFs, but are exclusively made with a ceramic cordierite material with a wall microstructure specifically engineered for gasoline exhaust. The porosity of this material can be higher than in a DPF to allow for the filtration of finer particulates (PM2.5 or smaller) prevalent in gasoline vehicle exhaust. There are also some differences in the filter configurations within the system design. These filters can withstand high temperatures >1100°C (2000°F), are extremely thermal shock resistant to allow for rapid heat-up on frigid days.

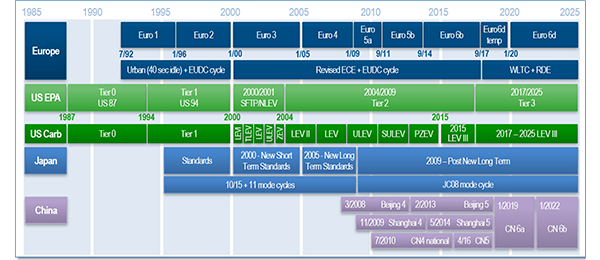

Since their introduction, advanced gasoline engines like high-performance gasoline-direct-injection (GDI) engines dominate engine design. They offer consumers better fuel economy without sacrificing engine performance. However, they produce a high number of fine particulates, such as PM2.5, that impact air quality and human health. As a result, Europe (with the introduction of EU6 regulations) and China (with China 6 regulations) introduced a particle limit for gasoline exhaust.

Particle emission limits for gasoline direct injection engines were first introduced in the regulations Euro 5a (PM) and Euro 6b (PN). To meet the current Euro 6d PN requirements, GDI engines should obtain a particulate filter (GPF).

Particulate filters for diesel engines (DPF) are well known already, but automotive science says do not directly compare them with gasoline filters due to significant differences.

- The accumulation of soot in GDI is much slower (since the content of particles is about five times (PM) or ten times (PN) lower than in diesel engines).

- The maximum temperature of exhaust gases in GDI is almost two times higher (which radically simplifies regeneration without various tricks necessary for diesels).

- Even despite a significantly lower concentration of oxygen in the exhaust gases of a gasoline engine.

- In GPF, the main role in particle capture is played by filter material, not layered soot, although ash deposits also improve filtration efficiency.

- Physical cleaning of GPF is not provided.

- Gasoline engines are more sensitive to exhaust backpressure.

- Resource tests show that using of low-SAPS motor oils is not necessary for GPF (the main share in ash deposits is iron oxide - wear products).

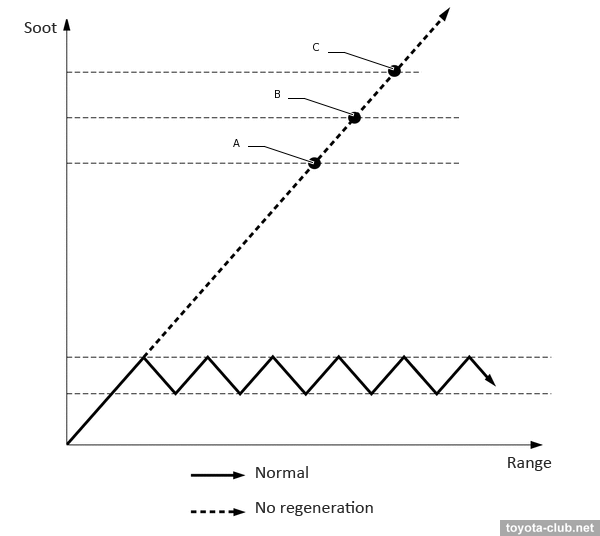

GPF is a ceramic structure of channels alternately closed on one or the other side, integrated in the exhaust pipe. As gases pass through the porous walls of the channels, solid particles and ash are deposited on their surface. GPF regeneration is passive: when the driving mode allows the filter to be sufficiently heated, the fuel supply is cut off, and clean air flows through cylinders into the exhaust, and the oxygen of the air oxidizes the accumulated soot particles.

The state of the filter is monitored using a differential pressure sensor (between the atmosphere and the exhaust upstream of GPF).

1 - differential pressure sensor, 2 - ECM, 3 - combination meter, 4 - catalyst, 5 - particulate filter (GPF), 6 - air-fuel ratio sensor, a - atmosphere

If for a long time the driving conditions do not allow to warm up the filter and start regeneration, then the soot accumulation becomes excessive. Upon reaching certain thresholds, the system will display an invitation to service, then turn on the malfunction indicator and begin to limit engine power.

Since the implementation of GPF a several new items were added in the familiar list of engine management system trouble codes.

Particle emission limits for gasoline direct injection engines were first introduced in the regulations Euro 5a (PM) and Euro 6b (PN). To meet the current Euro 6d PN requirements, GDI engines should obtain a particulate filter (GPF).

GPF is a ceramic structure of channels alternately closed on one or the other side, integrated in the exhaust pipe. As gases pass through the porous walls of the channels, solid particles and ash are deposited on their surface. GPF regeneration is passive: when the driving mode allows the filter to be sufficiently heated, the fuel supply is cut off, and clean air flows through cylinders into the exhaust, and the oxygen of the air oxidizes the accumulated soot particles.

Particulate filters for diesel engines (DPF) are well known already, but automotive science says do not directly compare them with gasoline filters due to significant differences.

- The accumulation of soot in GDI is much slower (since the content of particles is about five times (PM) or ten times (PN) lower than in diesel engines).

- The maximum temperature of exhaust gases in GDI is almost two times higher (which radically simplifies regeneration without various tricks necessary for diesels).

- Even despite a significantly lower concentration of oxygen in the exhaust gases of a gasoline engine.

- In GPF, the main role in particle capture is played by filter material, not layered soot, although ash deposits also improve filtration efficiency.

- Physical cleaning of GPF is not provided.

- Gasoline engines are more sensitive to exhaust backpressure.

- Resource tests show that using of low-SAPS motor oils is not necessary for GPF (the main share in ash deposits is iron oxide - wear products).

The state of the filter is monitored using a differential pressure sensor (between the atmosphere and the exhaust upstream of GPF).

The internal combustion engine is a marvel of engineering! It’s not likely going anywhere soon. It will most likely get multiple fuel sources in the coming years such as CNG (again) Hydrogen is becoming an emerging technology for the ICE as well. ICE will be a viable source for Hybrid and electrical generation systems and applications. A bit of trivia .. In 1966 and up to about 79, we had an emission device called a “Nox Kit” It was a small bag with a rubber plug and a sticker you paced on the dash. The idea was to plug off the vacuum advance port at the ignition distributor and plug of the source vacuum causing the ignition timing to not advance with vacuum. The reduction in timing would lower NOX emissions.

The industry has seen hundreds of systems and more to come! The upside to all this for a Technician? they all do the same thing.

Gasoline engines are fueled with two chemical compounds, gasoline and air. Gasoline is made of two elements, hydrogen (H2) and carbon (C). In the form of gasoline, these two chemicals combine to make what we call a hydrocarbon (HC). Air is mostly made of two elements, oxygen (O2) and nitrogen (N2).

All the systems are designed to reduce:

Carbon monoxide (CO) – An odorless, tasteless, poisonous gas, carbon monoxide can cause a variety of health problems and even death. Many urban areas experience critically high levels of carbon monoxide, especially during the cold winter months when engines take longer to warm up and run cleanly

Unburned hydrocarbons (HC) – Responsible for causing a variety of respiratory problems, unburned hydrocarbons can also cause crop damage and promote the formation of smog

Oxides of nitrogen (NOX) – Like unburned hydrocarbons, oxides of nitrogen cause respiratory problems and promote the formation of smoFor the most part, none of these chemical compounds are harmful; however, environmentalists argue that excessive amounts of carbon dioxide promote the formation of the greenhouse effect. Nonetheless, H2O, CO2 and N2 are the most desirable by-products of combustion, and automotive engineers strive to create emission control systems that allow a vehicle to produce only these three chemical groups.

Recapping... Direct Injected Gasoline Engines are going to see a GPF placed in the exhaust system. More complexity, cost and potential issues for consumers in the USA market. For Technicians additional diagnosis and repair training and Workshop owners another potential revenue stream after the warranty period.

Login to join the conversation

What other users have contributed